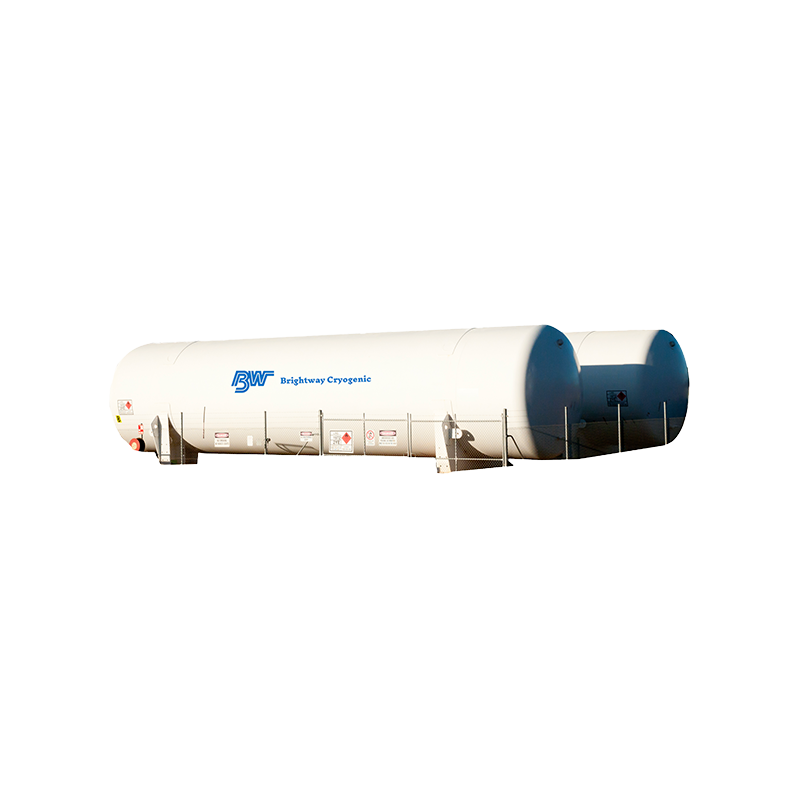

A cryogenic liquid storage tank is a specialized type of storage tank used for the storage of cryogenic liquids, which are substances that have very low temperatures and boil at temperatures below -150°C (-238°F). Cryogenic liquids include liquid nitrogen, liquid oxygen, liquid argon, and liquefied natural gas (LNG).

These tanks are designed to store these cryogenic liquids at very low temperatures, typically below -150°C, at high pressures. They are constructed using materials that can withstand these extreme conditions, such as stainless steel or aluminum, and have a double-walled design that allows for the storage of these extremely cold substances without causing damage to the outer tank.

Cryogenic liquid storage tanks are used in a variety of industries, including medical and pharmaceutical research, cryopreservation of biological samples, and the production and transportation of liquefied natural gas. These tanks are critical components in many processes, and their safe and reliable operation is essential to ensure the integrity of the substances they contain.

What is micro bulk tank?

A micro bulk tank is a type of tank used for storing and transporting cryogenic gases such as liquid nitrogen, liquid oxygen, and liquid argon. It is a small-scale bulk storage tank, designed for applications where a high volume of gas is needed, but not to the extent where a large bulk tank is required.

Micro bulk tanks typically have a capacity between 450 and 5000 liters, and they are used in a variety of industries, including medical, biotechnology, food and beverage, and welding. They are often used in applications where frequent refilling is not practical, but a continuous supply of gas is required.

The tanks are designed with safety features to prevent overpressure, overfilling, and other hazards. They also come equipped with pressure gauges and level indicators to ensure that operators can monitor the amount of gas in the tank at all times.

Overall, micro bulk tanks offer a convenient and cost-effective solution for storing and transporting cryogenic gases, especially in situations where a large bulk tank is not feasible.

Micro bulk tanks are small to medium-sized tanks used for storing and transporting cryogenic liquids such as liquid nitrogen, oxygen, and argon. Here are some advantages of using micro bulk tanks:

Cost-effective: Micro bulk tanks are more cost-effective than traditional bulk storage tanks since they require less space and can be installed quickly and easily.

Space-saving: Since micro bulk tanks are small in size, they require less space for storage compared to traditional bulk tanks, making them ideal for small workspaces.

Easy to handle: Micro bulk tanks are easy to handle and transport since they are small and lightweight.

Better control: Micro bulk tanks offer better control over the use of cryogenic liquids since they allow for precise dispensing and metering of the liquid.

Reduced downtime: Micro bulk tanks are equipped with automatic refill systems that ensure a continuous supply of cryogenic liquids, reducing downtime caused by running out of liquid.

Safer: Micro bulk tanks are equipped with safety features such as pressure relief valves and alarms that ensure the safe handling and storage of cryogenic liquids.

Overall, micro bulk tanks are a convenient and cost-effective way to store and transport cryogenic liquids for a wide range of applications.