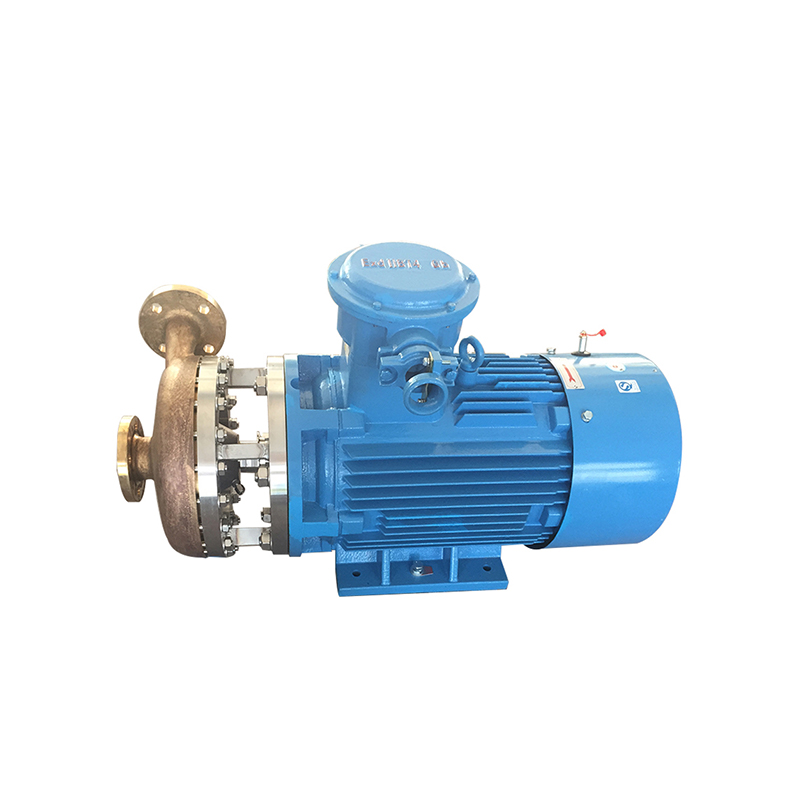

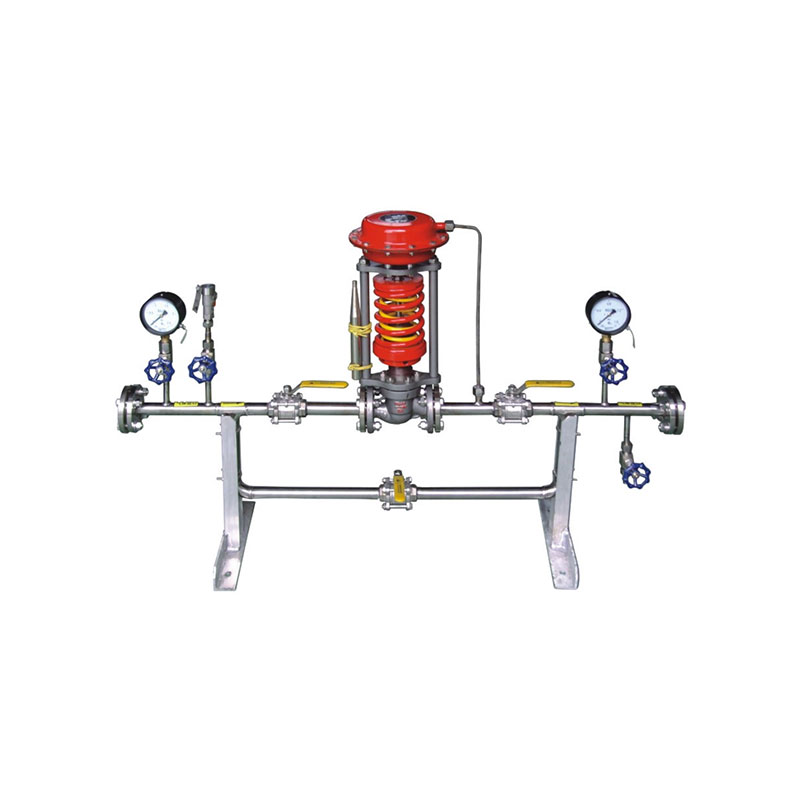

Dewar cylinders are ultra-vacuum insulated stainless steel pressure vessels designed for storage, transportation and use of liquid oxygen, liquid nitrogen, liquid argon or carbon dioxide.

The DPL series containers are vacuum insulated, stainless steel containers designed to store and transport cryogenic liquid oxygen, nitrogen or argon. Containers may be used for over the road transportation of cryogenic fluids, as well as on-site storage and supply in a wide range of applications.

As rugged, long holding time, self-contained gas supply systems, these cylinders are capable of providing contonuous flow rates of up to 350cfh(9.2 cu.m/h)with a delivery pressure of approxomately 100psig (6.9bar/690 kpa)

The DPL Series containers are very rugged liquid cylinders. All cryogenic liquid cylinderd have an inner container and an outer container with an insulated vacuum space between them. Any abuse(dents, dropping, tip-over,etc) can affect the integrity of containers insulation system.