Industry knowledgeA cryogenic centrifugal pump is a type of pump that is designed to handle extremely cold fluids, typically at temperatures below -150°C (-238°F). These pumps are commonly used in industries such as liquefied natural gas (LNG), aerospace, and medical equipment manufacturing, where cryogenic fluids such as liquid nitrogen, liquid oxygen, or liquid helium are required.

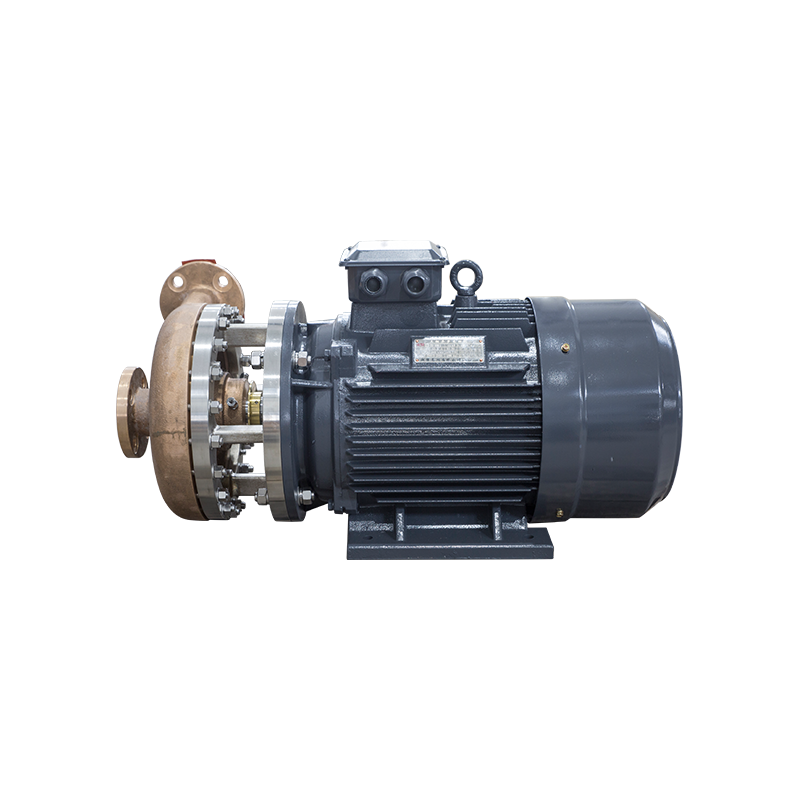

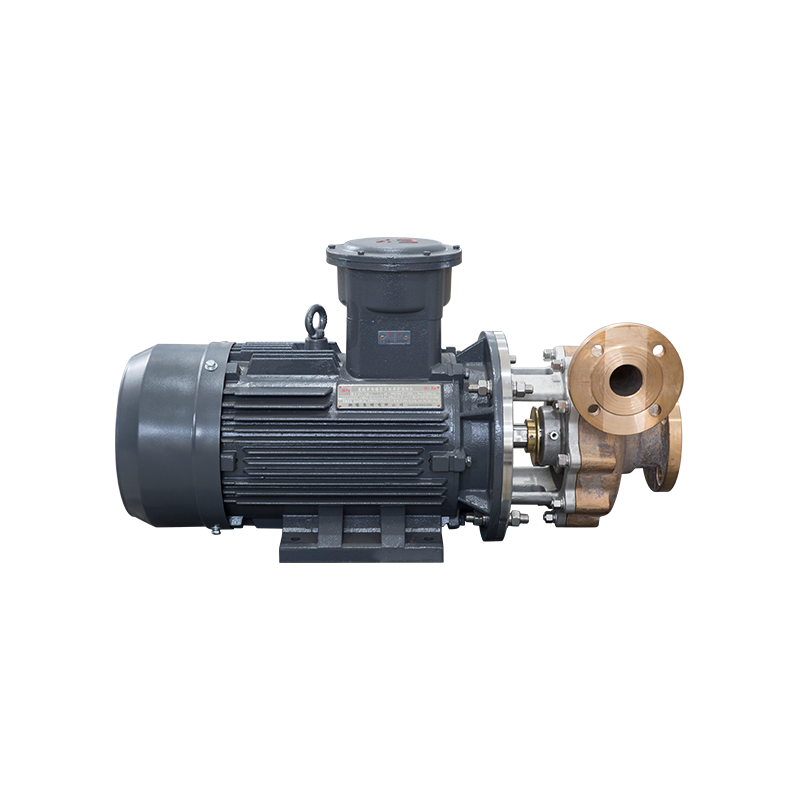

Cryogenic centrifugal pumps are designed with specialized materials and features to handle the unique properties of cryogenic fluids. These materials are chosen for their ability to withstand the low temperatures and maintain their strength and durability over time. The pump typically has an enclosed housing that helps to prevent heat transfer from the surroundings, which could cause the cryogenic fluid to vaporize or lose its low temperature.

One important feature of cryogenic centrifugal pumps is the use of a magnetic drive or magnetic coupling, which eliminates the need for seals and prevents any leakage of the cryogenic fluid. This is important because cryogenic fluids are typically hazardous and can be dangerous to handle.

Cryogenic centrifugal pumps can be used for a variety of applications, such as transferring cryogenic fluids from one storage tank to another, supplying cryogenic fluids to industrial processes, and filling or emptying cryogenic storage containers. These pumps are also used in research laboratories and medical facilities for cryogenic preservation of biological samples and tissue.

Cryogenic centrifugal pumps are specifically designed to handle extremely low-temperature fluids, such as liquefied natural gas (LNG), liquid oxygen, liquid nitrogen, and other cryogenic liquids. These pumps use centrifugal force to transfer fluids and are commonly used in industries that require the transportation and handling of cryogenic fluids, such as the energy, medical, and aerospace industries.

Some common applications of cryogenic centrifugal pumps include:

Storage and transportation of LNG: Cryogenic centrifugal pumps are used to transfer LNG from storage tanks to transportation vessels such as tankers or trucks.

Aerospace industry: These pumps are used in rocket propulsion systems, cooling systems, and to handle cryogenic fuels.

Medical industry: Cryogenic centrifugal pumps are used in medical facilities to transport and store liquid nitrogen and oxygen for medical applications such as cryosurgery and cryopreservation.

Energy industry: Cryogenic centrifugal pumps are used in various industrial processes that involve the handling of cryogenic liquids such as liquefaction, gas separation, and refrigeration.

Overall, cryogenic centrifugal pumps play a crucial role in industries that require the handling of cryogenic fluids and are essential in ensuring the safe and efficient transfer of these liquids.