Applications

- Road trailers unloading, storage tank and ISO tanker loading & unloading

- Bunkering

- Process and back-up operations, petrochemical industry applications

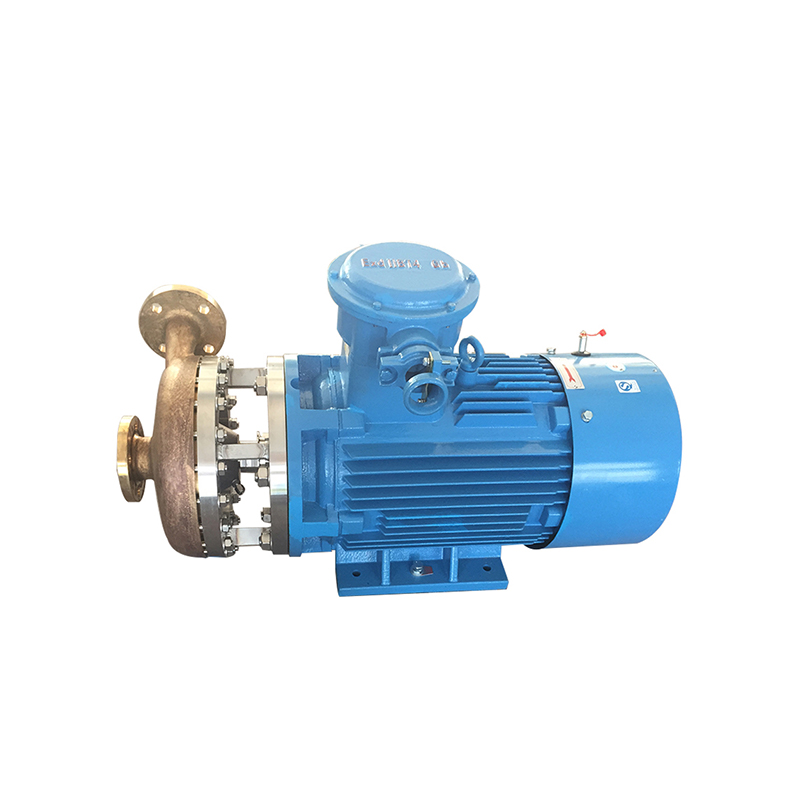

Technical features

- Electric motor and direct transmission

- Mechanical seal

- Inducer to minimize required NPSH

- Low noise emission

- Easy operation

The working principle of centrifugal pump is that when the centrifugal pump works, the liquid is constantly sucked into the pump by the pressure difference between the pump and the pump, and the liquid obtains kinetic energy by the high-speed rotation of the impeller. The liquid kinetic energy is converted into pressure energy by diffuser or guide vane.

Main technical parameters

Flow range: 5m/h-200 m3/h

Head: 10m- 1000 m

Fluid: LOX , LIN , LAr, LNG

Optional configuration

- Counter flanges

- Filter Flexible hoses for suction and discharge lines

- Leakage detection by temperature sensor

- Flushing system with nitrogen gas

- Temperature sensor for cooling down

- Electrical control panel Motor suitable for VFD

- Completely automated systems available on demand

- Mobile skid available on demand

HAVEN'T FOUND THE PRODUCTS YOU WANT?

Customized with drawings and samples

CONTACT US