Common problems of liquid oxygen in various scenarios

1. Each customer shall establish a sound technical operation specification for the application of liquid oxygen.

2. It is forbidden to use fire or electric heater for vaporization of liquid oxygen vaporization equipment.

3 before the liquid oxygen tank is put into use, the system shall be subject to hydrostatic test, deoiling and purging with dry N2 of diaphragm vacuum pump. When the steam leakage point in the tank is not higher than - 45 ℃, it can be delivered for use.

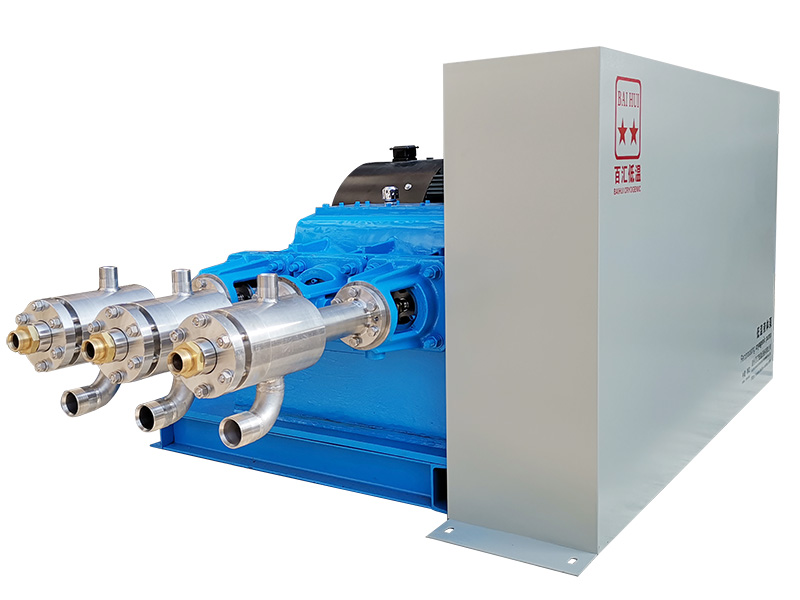

4 when multi-level liquid oxygen pump is selected, a protective wall conforming to safety regulations shall be built around the liquid oxygen pump, and the electrical switch shall be installed in the wall.

a) The sealing gas of pump casing shall be N2 of dry diaphragm vacuum pump. The pressure and total flow of sealing gas shall be strictly controlled to meet the provisions of the design scheme.

b) The lubricating oil of pump rolling bearing shall be selected according to the technical characteristics of machinery and equipment, and the lubricating oil that can withstand high and low temperature test and is not easy to ignite shall be selected.

c) After parking and before restarting the liquid oxygen pump, use N2 of the diaphragm vacuum pump at normal temperature to carry out purging; Before start-up, after sufficient quench, open the gate for inspection, and run after confirming that there are no abnormal conditions.

5. The O2 temperature behind the liquid oxygen vaporizer shall be strictly supervised and shall not be less than - 10 ℃.

6. The pipeline before liquid charging shall be equipped with emergency shut-off valve, valve and drain valve, and the pipeline after charging shall be equipped with check valve.

7. It is forbidden to store inflammables, explosives, chemicals and dirt around the liquid oxygen drain outlet. The pavement around the liquid oxygen drain outlet shall not be constructed with flammable, flammable and explosive raw materials (asphalt, etc.).

8. A professional analyzer shall be set and equipped with professional staff to analyze the acetylene gas composition in the liquid oxygen storage tank at least once a week × Liquid oxygen shall be discharged at 10-6.

9 it is forbidden to use vessels that have not been solved by deoiling to contain liquid oxygen.