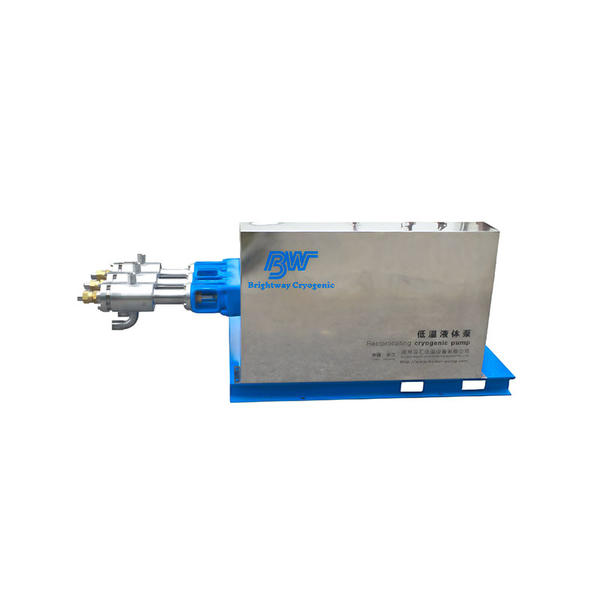

Cryogenic liquid pumps are designed to transfer and handle extremely low-temperature liquids, such as liquid nitrogen and liquid helium. They come with a variety of features that make them well-suited for different types of applications. Some common features include:

Low-temperature capability: Cryogenic liquid pumps are designed to operate at extremely low temperatures, typically down to -196 °C (-320 °F)

High-efficiency: Cryogenic liquid pumps have high-efficiency motors that can handle cold temperatures and still provide high flow rates.

Low NPSHr: Cryogenic liquid pumps have a low Net Positive Suction Head Required (NPSHr) which allows them to be used in applications where the suction pressure is low.

Materials: Cryogenic liquid pumps are typically made of materials that are resistant to the low temperatures and corrosive nature of cryogenic liquids, such as stainless steel, titanium, or aluminum.

Seals: Cryogenic liquid pumps have special seals that can handle low temperatures and prevent leaks.

Lubrication: Cryogenic liquid pumps have lubrication systems that can handle low temperatures, typically using synthetic lubricants.

Safety features: Cryogenic liquid pumps often have safety features such as pressure relief valves and low-level alarms to prevent overpressure and leaks.

Flow rate: Cryogenic liquid pumps come in a variety of flow rates, depending on the application and the amount of liquid that needs to be pumped.

Control systems: Cryogenic liquid pumps can come with control systems that allow the user to adjust the flow rate, pressure, and other parameters.

The function of the drive end of the pump is to change the rotating motion of the motor into a reciprocating motion and slow down the speed, and transfer the output power of the motor to the bottom of the cold end. The motor is converted and slowed down by the belt pulley, drive shaft, eccentric wheel, connecting rod and cross head components. The shaft, eccentric wheel and bearing structure of the transmission system are splash oil type, which makes the life of the power system greatly extended. The compression end of the cold end consists of a filter, a cylinder liner, a pump body, a piston assembly, a seal ring, a liquid inlet valve, a liquid discharge valve, etc.