Handling cryogenic fluids in centrifugal pumps can pose several safety considerations that must be managed to ensure safe and efficient operation. Cryogenic fluids, such as liquid nitrogen, oxygen, and hydrogen, are gases that have been cooled to extremely low temperatures, typically below -150°C. These fluids can be dangerous to handle due to their low temperatures and potential for rapid expansion when exposed to warmer temperatures.

Some safety considerations associated with handling cryogenic fluids in centrifugal pumps include:

Cold Burns: Cryogenic fluids can cause severe cold burns if they come in contact with skin or eyes. Contact with the cryogenic fluid can result in tissue damage, frostbite, and even the loss of limbs in extreme cases.

Fire and Explosion Hazards: Cryogenic fluids can cause fires and explosions if they come in contact with materials that can ignite or react with them. Cryogenic fluids can also cause materials to become brittle and susceptible to fracture, which can lead to structural failure.

Pressure Build-up: Cryogenic fluids can rapidly expand when exposed to warmer temperatures, which can result in a rapid build-up of pressure within the pump. This pressure can cause the pump to rupture or fail, potentially causing injury or damage to surrounding equipment.

To manage these safety considerations, several measures can be implemented, including:

Personal Protective Equipment (PPE): Workers handling cryogenic fluids should wear appropriate PPE, including gloves, face shields, and full-body clothing to protect against cold burns and potential exposure to the fluids.

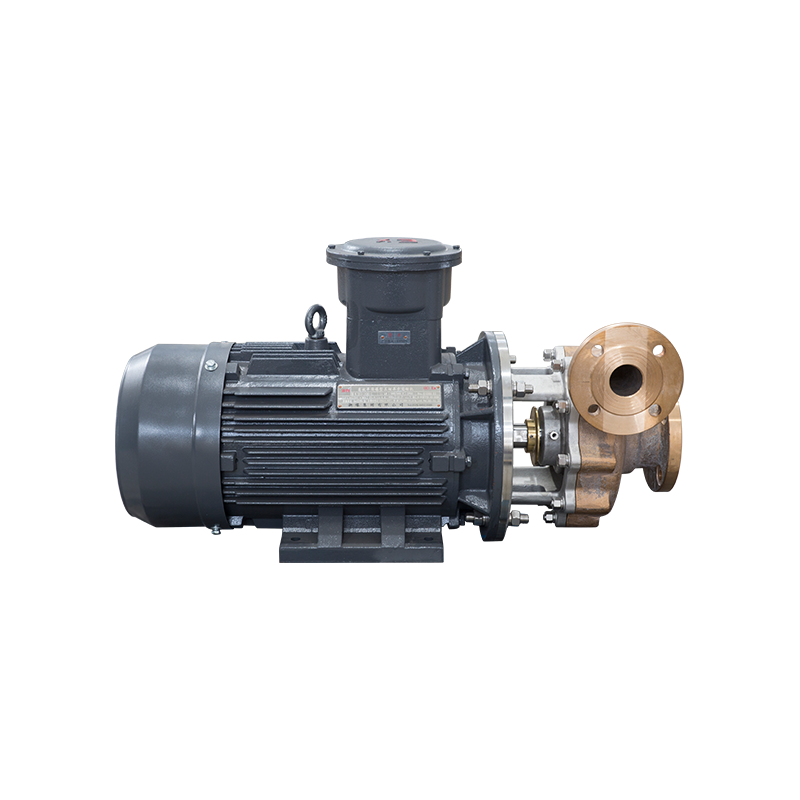

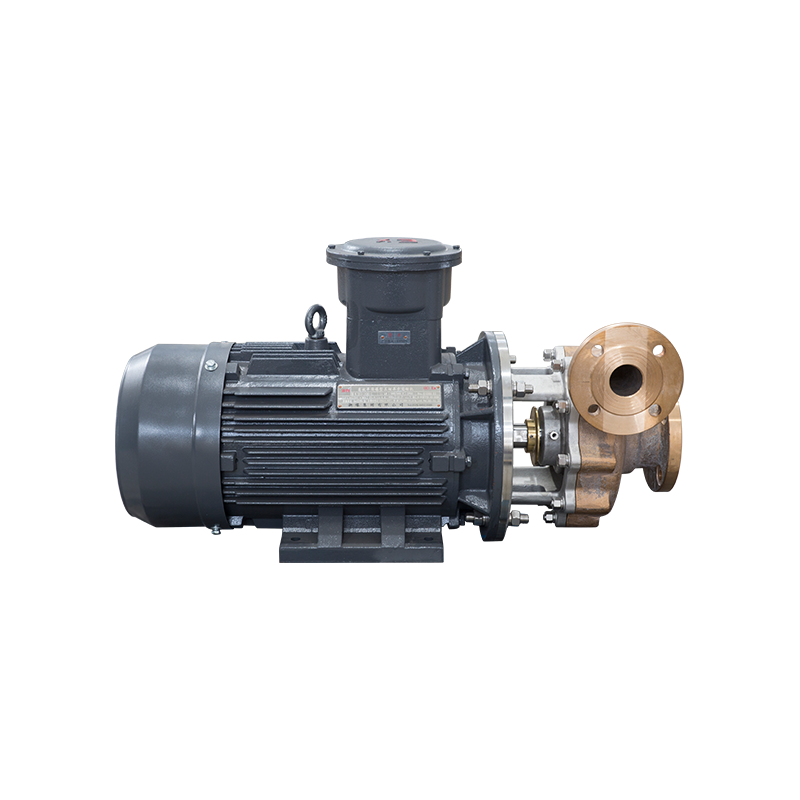

Equipment Design: Pumps and other equipment used to handle cryogenic fluids should be designed to withstand the low temperatures and pressure build-up associated with these fluids. The equipment should also be made of materials that can withstand exposure to cryogenic fluids.

Proper Training: Workers should receive adequate training on the safe handling and operation of cryogenic fluids and associated equipment. This training should include emergency response procedures in case of an accident or equipment failure.

Monitoring and Maintenance: Regular monitoring and maintenance of the pumps and associated equipment can help detect potential issues before they become a safety hazard. This includes regular inspection and testing of equipment to ensure that it is functioning properly and in good condition.

Overall, proper management of safety considerations associated with handling cryogenic fluids in centrifugal pumps requires a combination of proper equipment design, adequate PPE, proper training, and regular monitoring and maintenance. By following these measures, workers can safely handle cryogenic fluids and minimize the risk of accidents and injuries.