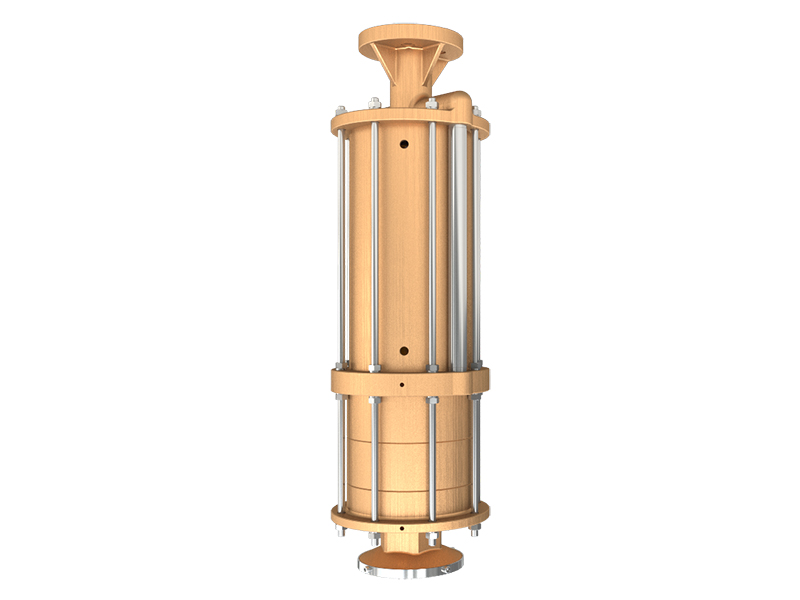

LNG submersible pump is mainly composed of submersible sewage pump body and pump tank. There are many hydraulic piston pump manufacturers in China.

Function of LNG submersible pump: LNG submersible sewage pump is a deep submersible centrifugal pump. The key function of LNG submersible pump is to operate the submersible sewage pump to transport LNG from the storage tank to the vehicle storage room when it is unable to fill the storage tank with LNG liquid by using its own working pressure. Heavy tanks.

The pump casing and motor penetrate into LNG, which reduces the loss of LNG and ensures the start-up of the pump. The shell of submersible sewage pump greatly reduces the cold loss of pipeline system and ensures the excellent operation standard of the pump; The column design allows the pump to operate smoothly and have a longer service life. LNG liquid "low feed is higher than".

The structure of LNG pump shell generally includes motor, main shaft bearing, rolling bearing, centrifugal impeller, deflector, etc., while the pump pool is generally a two-layer vacuum pump insulation structure, and the pump pool is generally equipped with temperature sensor, water level sensor and liquid level sensor,

The key socket of pump niaoming stream includes liquid inlet, air supply outlet and liquid outlet. The auxiliary socket includes the sensor data signal outlet socket in the pump pool, the water level sensor transformer ground wire socket, the temperature sensor transformer ground wire socket and the power plug socket.

LNG submersible pump? Cryogenic pump sump:

The submersible sewage pump is installed in the pump pool. The design scheme of pump automobile oil tank and the working pressure are 1.6Mpa. All construction has no sealing parts. Compact structure, easy assembly and maintenance. The quench time is short and can operate in a short time. The cryogenic pump sump has the following characteristics:

① The heat insulation structure of the pump sump cover is designed, which significantly improves the heat resistance of the pump sump;

② The design scheme of inlet and outlet liquid integrated vacuum solenoid valve channel not only improves the thermal insulation characteristics, but also improves the pipeline layout, and the overall actual effect is very beautiful;

③ Fill the pump sump with liquid according to the oil return hole;

③ The pump sump cover is tightly installed with working pressure, temperature sensor, pump sump liquid phase pipe and other easy-to-use machinery and equipment;

④ The pump sump has sufficient heat insulation characteristics. The vacuum pump shell and top cover of the pump shell have no frost during operation, and the ultra-low temperature liquid volatilization within 24 hours is ≤ 30%.

⑤ The design scheme of pump automobile fuel tank is convenient for maintenance, and the disassembly and replacement of spare parts of cryogenic pump shall not exceed 8 hours.