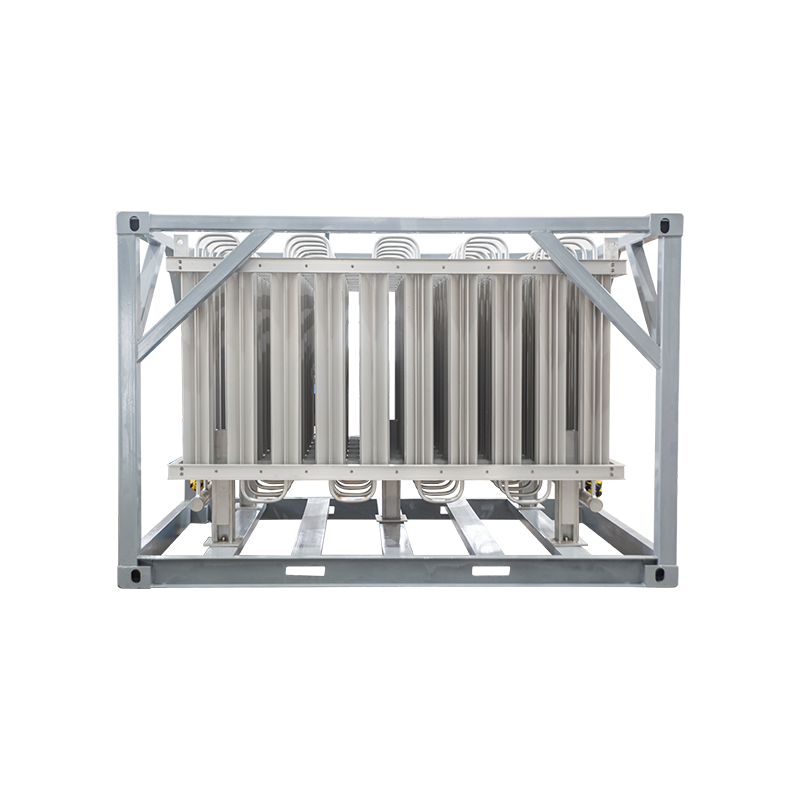

Characteristics:

1. The cooling insulation structure of the pump pool cover is designed, and the heat insulation performance of the pump pool is significantly improved;

2. The integrated vacuum pipe design of the inlet and outlet pipe not only improves the thermal insulation performance but also optimizes the pipeline layout, and the overall effect is very beautiful;

3. Fill the pump pool with liquid through the return port

4. A utility device with pressure and temperature sensors and a pump pool meteorological tube is installed on the pump pool cover;

5. The pump pool has sufficient cooling performance. The vacuum shell and upper cover of the pump body have no frosting phenomenon during operation.

6. The design of the pump pool is easy to maintain, and it takes less than 8 hours to replace the wearing parts of the cryogenic pump.

Main Technical Parameters

Flow:2m3/h-25m3/h

Head:15m-450m

Rotating speed: 1000-6000rpm

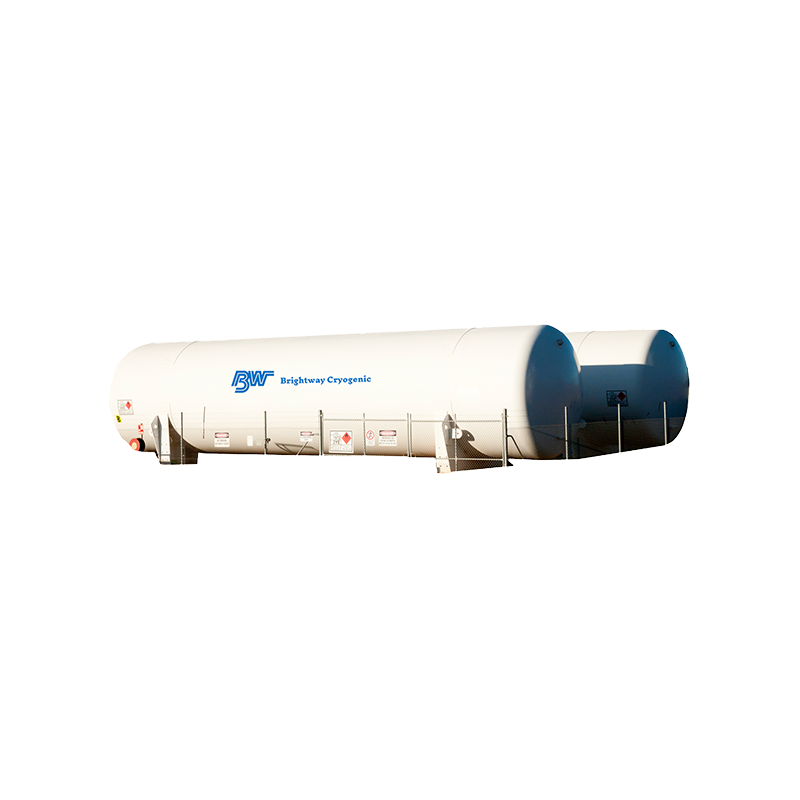

Application

- LNG vehicle filling station

- LNG receiving station

- Filling LNG Dewar cylinder

- Filling LNG tanker

- Transshipment, conveying LNG,

- LNG zero leakage environment

Advantage of Bright way's submersible pump

- Zero leakage and reduces the loss of cold. Quick start-up;

- Install an inductor in the liquid inlet which greatly reducing NPSH requirements.

- For different performance conditions, Brightway use VFD motor

- Brightway adopt high quality imported low temperature bearings, prolong the service life of pump

HAVEN'T FOUND THE PRODUCTS YOU WANT?

Customized with drawings and samples

CONTACT US