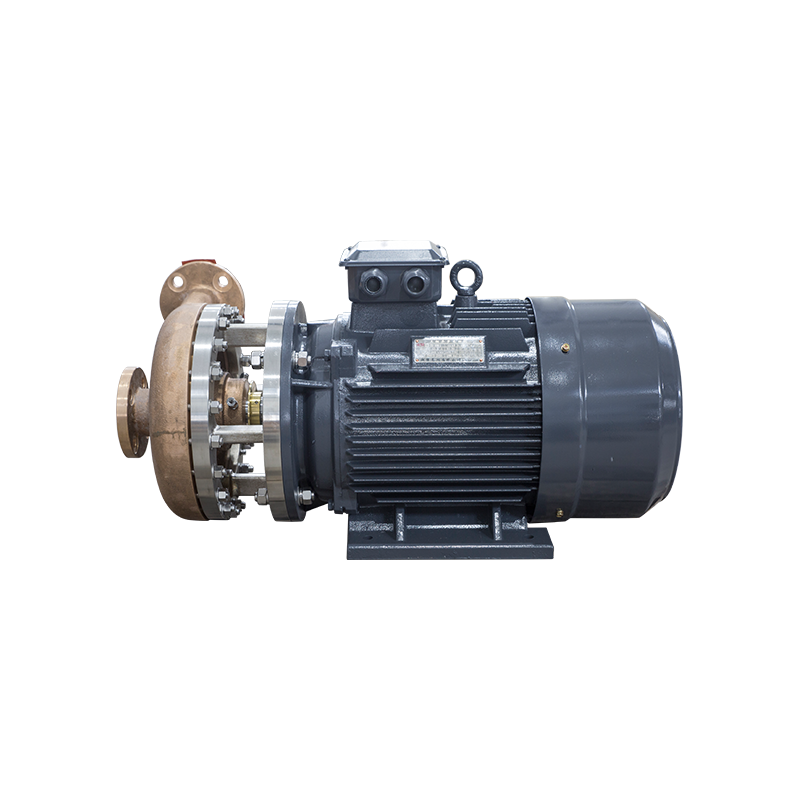

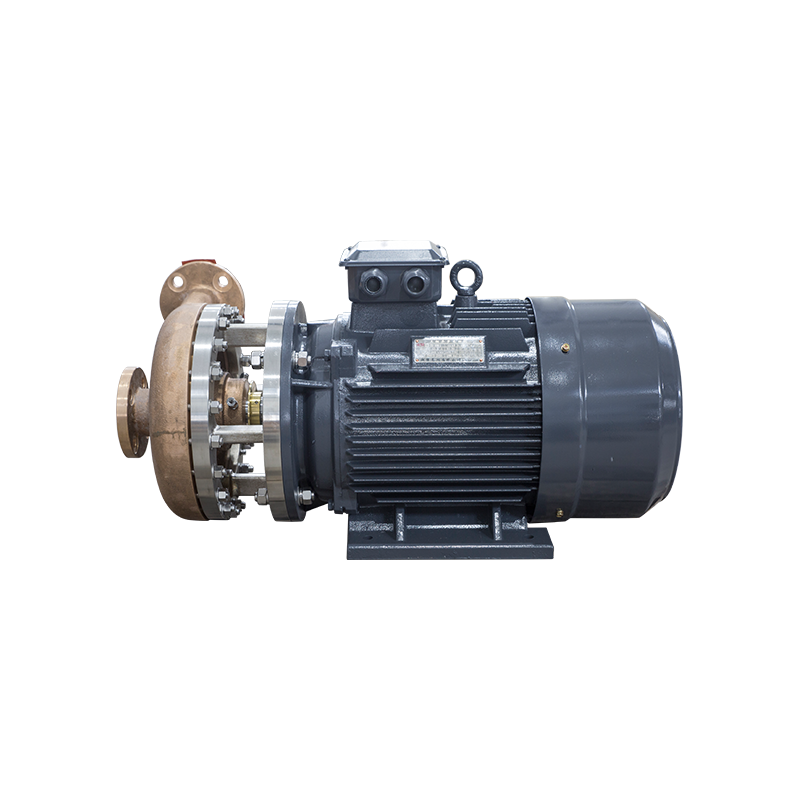

Cryogenic centrifugal pumps are specifically designed to handle and transfer cryogenic fluids, which are substances at extremely low temperatures, typically below -150°C (-238°F). They are often used in applications involving the handling of liquefied natural gas (LNG), liquid oxygen, liquid nitrogen, and other cryogenic fluids.

When comparing cryogenic centrifugal pumps to other types of pumps, such as positive displacement pumps or reciprocating pumps, several key differences can be observed:

Working Principle: Cryogenic centrifugal pumps operate based on the principle of centrifugal force. They use an impeller to generate a centrifugal force that imparts energy to the fluid and moves it through the pump. Positive displacement pumps, on the other hand, use mechanisms like reciprocating pistons or rotating gears to displace a fixed volume of fluid per cycle.

Flow Rate and Pressure: Cryogenic centrifugal pumps are generally better suited for high-flow, low-pressure applications. They can handle large volumes of cryogenic fluids efficiently. Positive displacement pumps, on the other hand, are capable of generating high pressures but typically have lower flow rates.

Efficiency: Cryogenic centrifugal pumps are known for their high efficiency in transferring cryogenic fluids. They can achieve high flow rates with relatively low power requirements. Positive displacement pumps may have lower efficiencies due to factors such as fluid slippage, leakage, and internal friction.

Maintenance and Reliability: Cryogenic centrifugal pumps often require less maintenance compared to positive displacement pumps. Positive displacement pumps have more moving parts, valves, and seals that may require regular inspection and maintenance to ensure proper operation. Cryogenic centrifugal pumps can be more reliable in continuous operation over extended periods.

Size and Footprint: Cryogenic centrifugal pumps are typically larger in size compared to positive displacement pumps. They require more space due to the impeller, housing, and associated components. Positive displacement pumps, especially reciprocating pumps, tend to be more compact and can be suitable for applications where space is limited.

Cost: The cost of cryogenic centrifugal pumps can vary depending on factors such as materials of construction, design specifications, and flow rates required. In general, cryogenic centrifugal pumps may be more expensive compared to positive displacement pumps for similar flow rates and pressure ratings.

It's important to note that the selection of a pump type depends on the specific requirements of the application, including the desired flow rate, pressure, temperature, and the nature of the fluid being handled. Consulting with pump manufacturers or experts can provide more detailed information and guidance for selecting the most appropriate pump for a particular cryogenic application.